TwinPack

Steam outputs from 30 t/h to 58 t/h

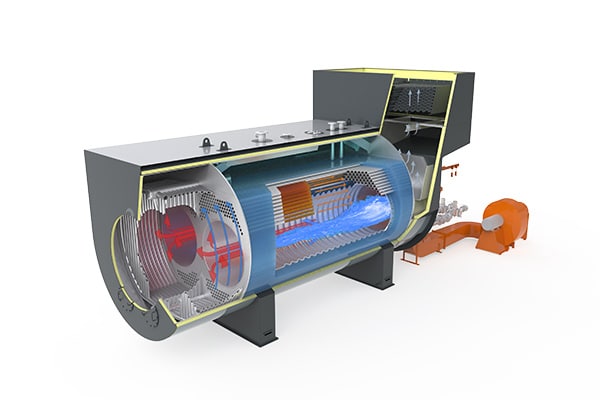

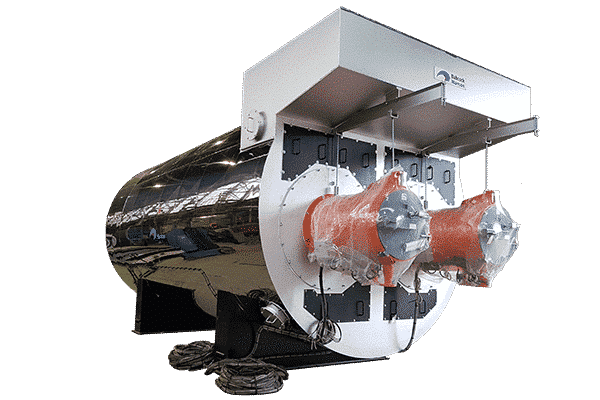

The TwinPack range of boilers is the latest design and has been developed using a combination of best available technologies to offer high reliability and maximum efficiency. Over a period of more than 50 years Babcock Wanson has built a reputation for excellence in the design and manufacture of Twin Furnace Boilers. These boilers were originally designed to meet the demands of high steam output users and to satisfy to the requirements of the European market for water tube boiler replacement.

High performance

Energy efficiency

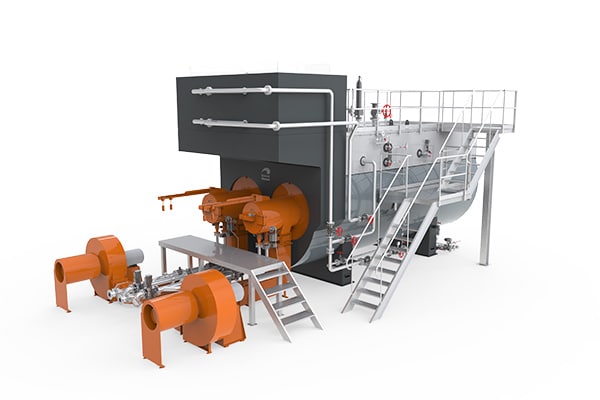

High operating efficiency is a key feature of Babcock Wanson boilers. When a TwinPack boiler is specified in conjunction with a Babcock Wanson Economiser and Heat Recovery System, net efficiencies of greater than 98% (with the R-Eco system) and 105% (with a condensing economiser) can be achieved. The Babcock Wanson Burner Management System and matched combustion head have been specifically designed for perfect control of excess air throughout the modulating range and non-degraded operation at very low load. The simultaneous operation of the burners guarantees a perfect thermal load distribution while ensuring maximum flexibility in operation and burner turndown ratios of up to 30:1 on natural gas.

Environmentally friendly

The perfect match between the boiler and burners guarantees optimal combustion and perfectly controlled emissions. Optimum efficiency and high burner turndown results in lowest practicable CO2 emissions and specialist burner technology ensures very low Nitrogen Oxide (NOx) emissions to satisfy all environmental demands and regulations.

Reliable and safe design

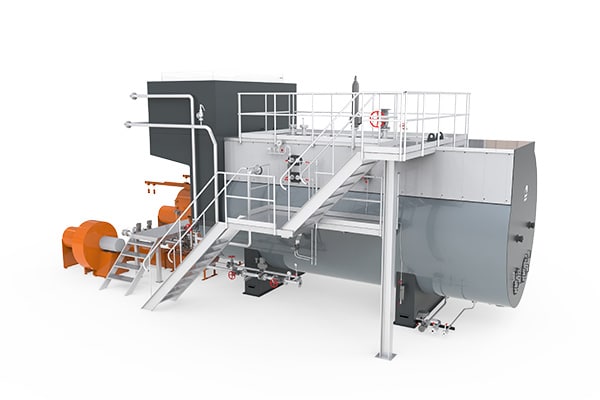

TwinPack boilers benefit from Babcock Wanson’s most advanced regulation and control system. For best performance the Navinergy system allows local operation via the boiler HMI plus remote monitoring through a web interface.

Reduced operating cost

Robust design for very long life

TwinPack boilers include a tubular construction flue gas reversal chamber. This technology, unique to Babcock Wanson, removes any requirement for furnace tube tie rods and allows high variations of steam demand whilst minimising mechanical stress on the pressure body. The TwinPack water tube reversal chamber also minimises boiler refractory requirements.

Easy access

TwinPack boilers include a tubular construction flue gas reversal chamber. This technology, unique to Babcock Wanson, removes any requirement for furnace tube tie rods and allows high variations of steam demand whilst minimising mechanical stress on the pressure body. The TwinPack water tube reversal chamber also minimises boiler refractory requirements.

Economic operation

All Babcock Wanson exclusive operating modes are available on our Twinpack boiler for both supervised or unsupervised operation (3 days, 7 days and even 30 days of continuous operation within authorised limits).

Why choose the TwinPack boiler from Babcock Wanson?

- High efficiency and very low emissions

- Compact design.

- Simple access for ease of maintenance

- Robust design for very long life

- Full economisers range

- Connectivity with our system

- Combustion air pre-heater options

- Mixed and dual fuel firing options

- O2 and CO trim options

- Simple 3- and 7-day unattended operation

- Complete steam system solutions

- Superheater options

TwinPack Fire Tube Steam Boilers

| TwinPack | Model | 30.0 | 34.0 | 38.0 | 42.0 | 46.0 | 50.0 | 54.0 | 58.0 |

|---|---|---|---|---|---|---|---|---|---|

| Steam Output (1) | Kg/h | 30 000 | 34 000 | 38 000 | 42 000 | 46 000 | 50 000 | 54 000 | 58 000 |

| Power Output (1) | kW | 20 600 | 23 450 | 26 225 | 28 950 | 31 715 | 34 330 | 37 000 | 39 600 |

| Width A (2) | mm | 5 700 | 5 750 | 5 900 | 5 950 | 6 050 | 6 150 | 6 250 | 6 350 |

| Length B (2) | mm | 12 750 | 13 200 | 13 300 | 13 500 | 13 800 | 14 050 | 14 100 | 14 500 |

| Height C (2) | mm | 5 400 | 5 450 | 5 600 | 5 650 | 5 750 | 5 850 | 6 100/td> | 6 200 |

| Weight-fully flooded | Kg | 90 350 | 100 800 | 106 900 | 110 800 | 118 000 | 122 200 | 136 200 | 141 200 |

(1) Steam output at up to 15 barg based on feedwater at 80°C.

(2) Overall diamensions include fitted burner and boiler mountings.