VAP-HP

From 232 to 2,325 kW – Up to 100 barg working pressure

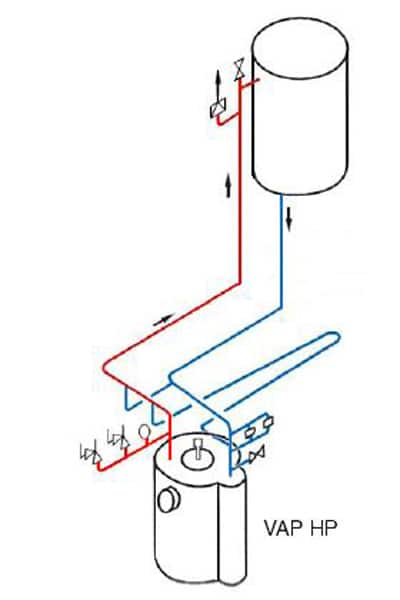

VAP-HP is a natural circulation high pressure steam generator designed for operation in a closed loop steam and condensate system. This type of closed loop configuration provides very high overall efficiency and the minimum of system losses throughout the operating range. The lack of blowdown, no requirement for softened make-up water and no need for ongoing chemical dosing make this the most cost effective and environmentally friendly design of steam generating equipment.

In its simplest application, the VAP-HP unit is operated in conjunction with a single user; steam produced by the boiler condenses at the user heat exchange surface producing condensate which returns under gravity to the boiler for reheating. VAP-HP requires minimal utilities consumption or use of space.

VAP-HP steam generator has been designed to operate in a diverse range of industries and to be able to serve all batch, continuous, or semi-continuous processes.

Simple Installation and Maintenance

- Integrated burner and control system provide fully automatic operation – all pre-mounted and wired for ease of site installation

- Supplied ready for connection to the water, steam, and electrical and fuel supply circuits

- Vertical configuration ensures minimum footprint

- No external condensate tanks or vessels required – system pipework provides all necessary condensate storage

- No circuit valves, fittings or traps. No feed or circulating pumps

- Water content is continuously monitored by duplex electronic fail-safe devices and an additional early warning unit may be fitted if required

Reliable Operation

- VAP-HP design incorporates a comprehensive arrangement of safety devices, not only for plant protection and general safety but also to ensure maximum plant availability

- Steam pressure relief valves are typically fitted with bursting disc protection to ensure to ensure complete system tightness

- Very high overall plant efficiency. No system losses

- High combustion efficiency

Environmentally Friendly

- Integral Babcock Wanson burner ensures minimal power consumption, simple maintenance and compliance with emission standards

- No regular water treatment, chemical consumption or blowdown required

VAP HP High Pressure Steam Generator

| VAP HP | Model | 200 | 400 | 600 | 1000 | 1500 | 2000 |

|---|---|---|---|---|---|---|---|

| Steam Production | kg/h | 608 | 1216 | 1824 | 3040 | 4560 | 6080 |

| Net Capacity | kW | 232 | 465 | 698 | 1163 | 1745 | 2325 |

Note – Steam production is dry saturated at 90 barg