AIM Composites a installé un système de fluide thermique Babcock Wanson Thermal Fluid System dans son usine de Waterbeach, Cambridgeshire, pour chauffer et contrôler le refroidissement de sa nouvelle presse produisant des panneaux et moulures légers pour le secteur du transport.

Système de chauffage et de refroidissement à fluide thermique pour fabricant de matériaux composites

IM Composites a installé un système de fluide thermique Babcock Wanson dans son usine de Waterbeach, Cambridgeshire, pour chauffer et contrôler le refroidissement de sa nouvelle presse produisant des panneaux et moulures légers pour le secteur du transport.

AIM utilise les matériaux composites les plus récents pour un gain de poids et des performances structurelles optimales. Ses produits sont utilisés sur l'ensemble du marché du transport, en particulier dans le secteur de l'aviation. Afin de produire de plus grands composants de haute qualité reproductible pour ce marché, AIM Composites a pris la décision d'installer une nouvelle presse plus grande.

Les presses existantes sur le site étaient alimentées à la vapeur et refroidies à l'eau, mais l'entreprise a constaté que le système n'offrait pas la précision et la souplesse de contrôle dont elle avait besoin. Forte d'une longue expérience dans ce domaine, la société Babcock Wanson, spécialisée dans le chauffage de process, a conseillé l'utilisation d'un système de chauffage à fluide thermique.

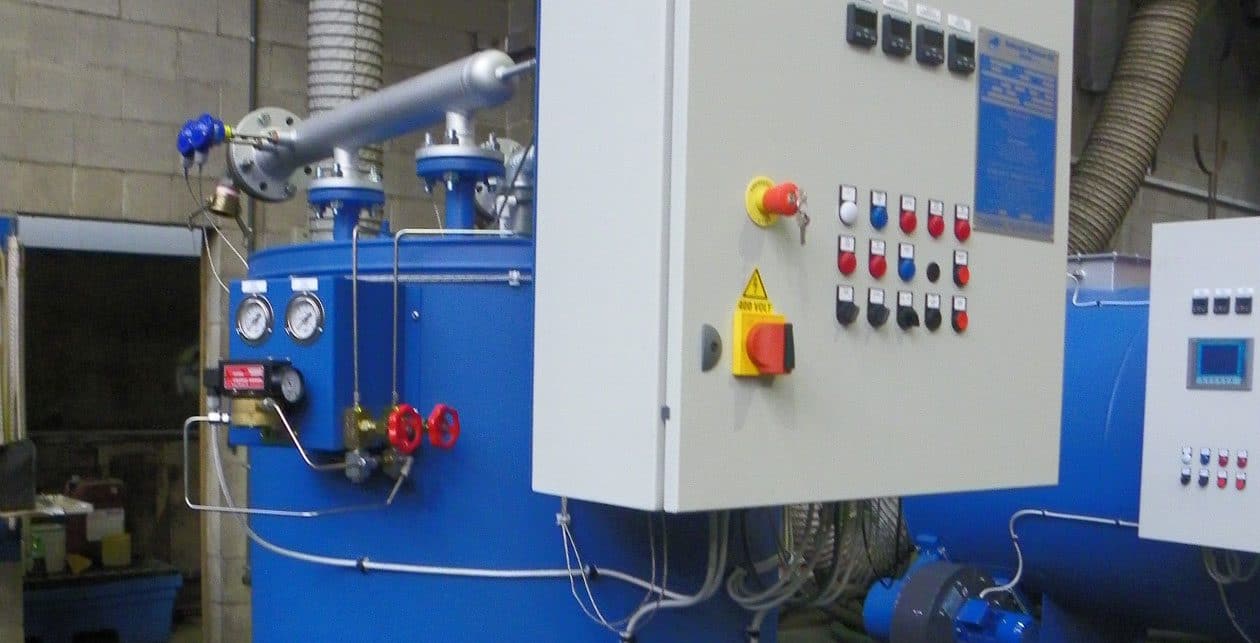

Chaudière à fluide thermique TPC1500B

Un réchauffeur de fluide thermique Babcock Wanson TPC1500B a été choisi pour fournir le chauffage, couplé à une boucle de régulation spécialement conçue pour refroidir le système selon un profil prédéterminé. Un seul fluide est utilisé dans l'ensemble du système pour une facilité d'utilisation et une efficacité maximale.

Le contrôle de l'ensemble du cycle chaud/froid est réalisé à l'aide d'une unité de contrôle de température sur mesure et d'un logiciel dédié, également conçu et installé par Babcock Wanson. Le logiciel unique piloté par menu permet de télécharger et de mémoriser jusqu'à 50 profils de chauffage/refroidissement, chaque profil offrant jusqu'à six niveaux de rampe de température et de temporisation. Une simple sélection à partir d'un menu permet ensuite au processus de s'exécuter entièrement automatiquement. Non seulement cela procure à AIM Composites une flexibilité exceptionnelle, mais le besoin minimal d'intervention de l'opérateur permet une plus grande rapidité et une meilleure répétabilité du processus. Toutes les données sont stockées dans le contrôleur pour être téléchargées et révisées au besoin, fournissant ainsi un enregistrement précis et simple du processus de traitement thermique - un outil utile pour aider AIM Composites à répondre aux exigences de ses clients.

L'avis du client

David Drewry, directeur technique d'AIM Composites, est très satisfait des résultats : "La conversion au chauffage et au refroidissement par fluide thermique a permis de réduire jusqu'à 30 % le temps de cycle du procédé. Cette amélioration significative de l'efficacité est évidemment un avantage clé pour nous. Parmi les autres avantages, mentionnons la réduction des coûts d'entretien, la réduction des coûts énergétiques (remplacement de trois chaudières à vapeur par une chaudière thermique) et l'augmentation de la surface au sol disponible (enlèvement de la chaufferie et de l'ancien système de refroidissement).

"Nous n'avions jamais travaillé avec Babcock et Wanson, mais j'ai trouvé que le service fourni était d'un très haut niveau."

Le système de fluide thermique TPC1500B permet non seulement de chauffer et de refroidir les presses actuelles de l'AIM, mais aussi de supporter une deuxième presse, si les cadences de production futures l'exigent.

Les réchauffeurs de fluide thermique de la série TPC sont des réchauffeurs de fluide thermique à passages multiples et à serpentins entièrement automatiques, équipés d'un brûleur intégré, d'un système de contrôle et de dispositifs de sécurité. Ils assurent une répartition optimale de l'échange thermique, une vitesse de fluide élevée et un contrôle spécialisé du débit pour une longue durée de vie du fluide et une sécurité maximale, le tout associé à de très faibles émissions et de faibles coûts de fonctionnement.

Témoignages de clients

Sam Robinson, responsable de l’ingénierie et de la maintenance des installations, Gurit Composite ComponentsLes chaudières sont bien conçues, faciles à entretenir et ont donné de bons résultats. Une unité existante sur le site a fonctionné environ 24 heures sur 24, 7 jours sur 7, 360 jours par an, avec une seule défaillance en huit ans. Les commandes sont simples, sans ajouts compliqués inutiles, ce qui est agréable ; elles sont pensées pour répondre aux besoins et fonctionnent très bien.

Andrew Taylor, Directeur, Freedom BreweryNous avons choisi le fluide thermique parce qu'il est plus économique à installer et à faire fonctionner, qu'il nécessite moins d'espace que la vapeur et qu'il offre une solution plus écologique.

Duncan McLeod, Directeur technique, Total Bitumen PrestonLes principaux avantages déjà tirés des chaudières EPC ? Une réduction des coûts de combustible et des émissions, une plus grande efficacité et le passage au gaz naturel au lieu d'un combustible lourd, ce qui a supprimé la nécessité de stocker le combustible sur place.

Jeff Farey, Responsable de la maintenance, Beardow Adams"Les chaudières Babcock Wanson se sont avérés fiables pour notre activité et ont toujours donné satisfaction"

David Drewry, Directeur Technique, AIM Composites"Nous n'avions jamais travaillé avec Babcock Wanson auparavant, mais j'ai trouvé le service fourni d'un très haut niveau".

Nicola Lord, Directeur d’usine , Blackburn Chemicals"Nous avons trouvé les équipements Babcock Wanson fiables et efficaces et nous recevons toujours un bon support de leur part".

Keith Netting, Responsable de l’industrialisation et du développement de produits, Gurit Composite Components"Les chaudières sont bien conçues, faciles à entretenir et ont donné de bons résultats. Une unité existante sur le site a fonctionné environ 24 heures sur 24, 7 jours sur 7, 360 jours par an, avec une seule défaillance en huit ans. Les commandes sont simples, sans ajouts compliqués inutiles, ce qui est appréciable; elles sont pensées pour répondre aux besoins et fonctionnent très bien".

Allan Goulden, Directeur de l’ingénierie, Eco-Oil"La réduction des coûts énergétiques était au cœur de nos préoccupations et nous savions que nous pouvions faire des économies considérables en passant de la vapeur au fluide thermique comme source de chaleur pour notre procédé industriel. Nous avons étudié les options de manière approfondie et avons conclu que Babcock Wanson offrait la meilleure solution. Jusqu'à présent, nous avons eu raison : le système a réduit nos coûts énergétiques et est facile à utiliser et à contrôler".

Douglas Watt, Ingénieur principal, Eastham Refinery Ltd"Les chaudières ont répondu à nos attentes et sont simples à utiliser. elles ont permis de réduire considérablement le coût du combustible par rapport à nos anciennes chaudières au fioul".

Peter Shrimpton, Responsable des projets d’ingénierie, Bridgnorth Aluminium Ltd"Nous ne connaissions pas Babcock Wanson, mais nous n'avons eu aucun problème avec eux ; il suffit de l'allumer et il fonctionne - c'est aussi simple que cela ! Le support que nous avons reçu de Babcock Wanson a également été excellent".

You must be logged in to post a comment.