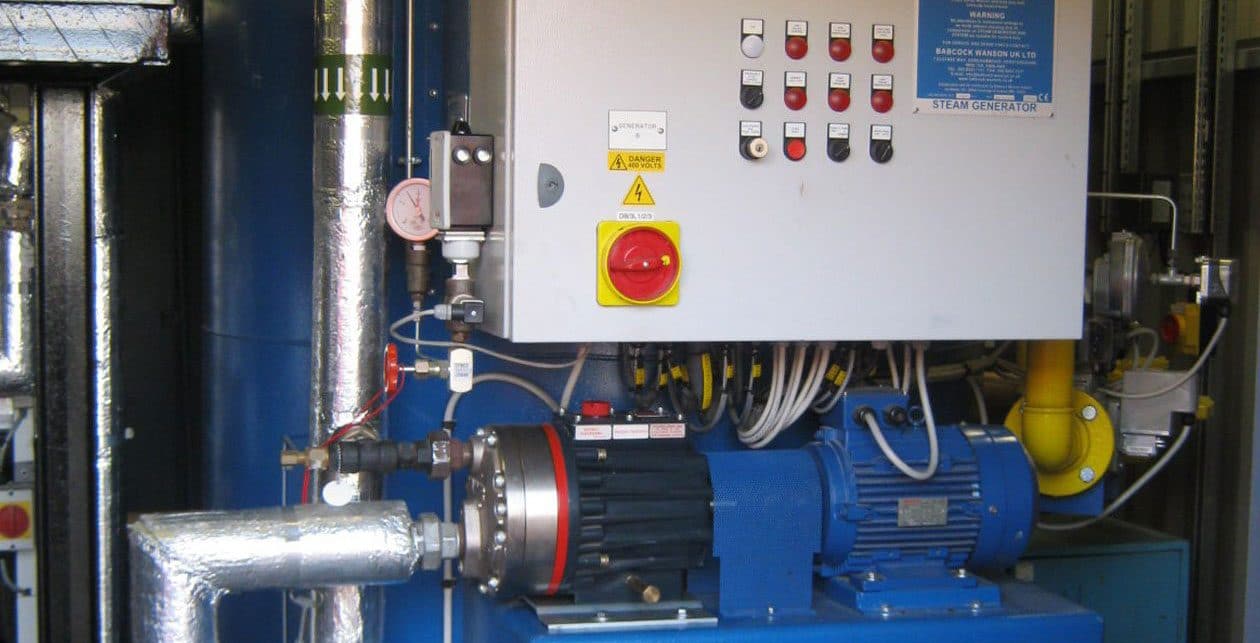

Babcock Wanson has supplied two 2000kg/h VPX Rapid Steam Generators to Martindale Pharma, a market leader in the manufacture and supply of specialty pharmaceuticals and services for healthcare professionals worldwide.

Steam Generators for Pharmaceutical Manufacturing

The two Steam Generators have been installed at Martindale Pharma’s principle site of manufacture in Romford, Essex, which specialises in the production of sterile ampoules, sterile screw cap bottles, non-sterile liquids, non-sterile suspensions and suppositories.

Steam is produced for a wide variety of uses across the Romford site, including the manufacturing production processes, production of Water for Injection (WFI) and a Pure Steam Generator (PSG), as well as heating for the company’s Air Handling Systems. The new VPX units have replaced four smaller generators that were unable to meet Martindale Pharma’s growth and subsequent capacity requirements.

VPX Vertical Coil Steam Generators

VPX vertical coil Steam Generators from Babcock Wanson feature three full gas passes plus an in-built combustion air pre heater to give high operating efficiency. With availability of steam from cold start in as little as three minutes and a low volume of water under pressure the VPX Steam Generator combines efficiency with safety, even at very high working pressure. They are rugged in construction and very compact.

The pressure containing coil design of the VPX Steam Generator forms the main combustion chamber with the second and third passes for the gasses going between the coil windings to ensure high gas velocity with good heat transfer and self cleaning of the smoke side. Accurate flame dimensions are important for any combustion device and the use of a purpose built and matched Babcock Wanson burner ensures long life and simple operation. The feed water system is simple in operation and easy to maintain, consisting of either a multi diaphragm type positive displacement pump driven from an inverter controlled motor for both accurate control and lowest electrical demand.

As there is no discernible water level with a coil type boiler, the need for water level gauge glasses and other devices normally associated with fire tube boilers is eliminated with the associated reduction in boiler house manning demands. This equals simple and safe operation at the lowest practicable operating cost.

More than just an Installation

To maintain the Steam Generators’ efficiency and maximise their working life, Martindale Pharma has signed up to Babcock Wanson’s Water Treatment Service operated in conjunction with water treatment specialist Deep Water Blue. Under this service Martindale Pharma benefits from the deployment of highly qualified, professional chemists who ensure the treatment and testing regime is completed to obtain an accurate picture of the site’s specific requirements under a variety of conditions; this ensures the most appropriate chemical dosing regime is always employed. In between scheduled consultancy visits the unique vSteam® web portal allows Martindale Pharma to simply enter daily readings on-line and receive real-time feedback support.

Mark McLean, Engineering Team Leader at Martindale Pharma, is very pleased with the service; “the service from Deep Water Blue has so far been really good and the internet based reporting system is a fantastic tool for daily feedback on the water conditions, with instant advice on what to do to rectify any reading starting to drift out of specification.”

In addition, the Babcock Wanson Water Treatment Service provides a five year corrosion warranty on the steam generator coil. In the unlikely event of feed water deficiencies causing the coil to corrode within the first five years, Babcock Wanson will replace it under warranty.

Customer Testimonials

Xabier Garcia Mitjavila, Corbion, Engineering team leader“Babcock Wanson ha resultado ser un importante colaborador de Corbion, ofreciéndonos soluciones de mejoras de eficiencia y seguridad que han supuesto además un significativo ahorro de coste.”

Antonio Llabería, Engineering Manager at Ercros Tarragona“Desde Ercros llevamos años colaborando con Babcock Wanson y destacamos la fiabilidad y robustez de sus productos, así como su capacidad para entender y adaptarse a nuestras necesidades.”

Sam Robinson, Gerente de Ingeniería y Mantenimiento de Planta, Gurit Composite Component"Las calderas están bien construidas, son fáciles de mantener y han funcionado bien. Una unidad existente en la planta ha funcionado aproximadamente 24/7 360 días con sólo un sólo fallo en ocho años. Los controles son sencillos sin ningún añadido complicado innecesario, lo cual es de agradecer; están construidos para llevar a cabo lo que se requiere y funcionan muy bien."

Andrew Taylor, Director de la Cervecería Freedom"Elegimos el fluido térmico porque era más económico a la hora de de instalar y operar, tiene un menor requerimiento de espacio que el vapor y proporciona una solución más ecológica."

Duncan McLeod, Gerente de Ingeniería, Total Bitumen Preston"Entre los principales beneficios que ya se han obtenido de las calderas EPC se encuentran la reducción de los costos de combustible y de las emisiones de la chimenea, una mayor eficiencia y el paso al gas natural en lugar del combustible pesado, lo que ha eliminado la necesidad de almacenamiento de combustible en el lugar."

Jeff Farey, Gerente de Mantenimiento, Beardow Adams“Las calderas Babcock Wanson han demostrado ser fiables en toda nuestra empresa (y) siempre ha dado un buen servicio.”

David Drewry, Director Técnico de AIM Composites"No habíamos trabajado con Babcock Wanson antes, pero he encontrado que el servicio prestado es de un nivel muy alto."

Nicola Lord, Gerente de la Fábrica de Productos Químicos Blackburn"Hemos encontrado que el equipo de Babcock Wanson es eficiente y fiable y han demostrado tener un buen servicio de atención al cliente."

Allan Goulden, Director de Ingeniería de Eco-Oil"Reducir los costos de energía era nuestro principal objetivo y sabíamos que podíamos hacer considerables ahorros al pasar del vapor al fluido térmico como fuente de calor para nuestro proceso. Investigamos las opciones a fondo y decidimos que Babcock Wanson ofrecía la mejor solución. Hasta la fecha se ha demostrado que tenemos razón: el sistema ha reducido nuestros costos de energía y es fácil de usar con muy buen control."

Douglas Watt, Ingeniero de Proceso Senior, Eastham Refinery Ltd."Las calderas han cumplido con nuestras expectativas y son fáciles de operar. Han resultado una reducción significativa del costo de combustible sobre nuestras anteriores calderas de aceite."

You must be logged in to post a comment.