One of Europe's leading food companies, Moy Park has installed two additional Babcock Wanson TPC1000B Thermal Fluid Heaters into its Craigavon, Co. Armagh site as part of a site expansion programme.

Thermal Fluid Heaters for the Food Industry

Moy Park specialises in fresh, high quality locally farmed poultry and complementary convenience food products. As part of its plans to increase processing capacity at the Craigavon site, the company has installed a new and very substantial capacity Spiral Oven. The TPC1000B Thermal Fluid Heaters, each rated at 1163kW output, provide heat for the new oven.

Babcock Wanson helped in the design of the heating system with Moy Park to allow for maximum flexibility. The system can be easily adapted for use with three of the existing thermal fluid heaters on the site, which currently feed existing ovens. This coupling of the systems is planned to provide an increased level of flexibility and best operational standby capacity. With a site that operates around the clock, this latter aspect is essential for the highest possible production security. For the same reason, Babcock Wanson had to complete the heater installation and integration into Moy Park’s production system to a tight schedule, with downtime for the start up of the new systems kept to an absolute minimum.

A Long Term Relationship

Babcock Wanson has enjoyed a long standing relationship with Moy Park stretching back more than 25 years. The TPC1000B Thermal Fluid Heaters – which now total nine at the site - are all in daily operation and have been in use as Moy Park’s prime equipment for high temperature process heating throughout that period. The heaters have proven to be extremely reliable for the company’s fryer and oven heating needs as well as being simple to operate.

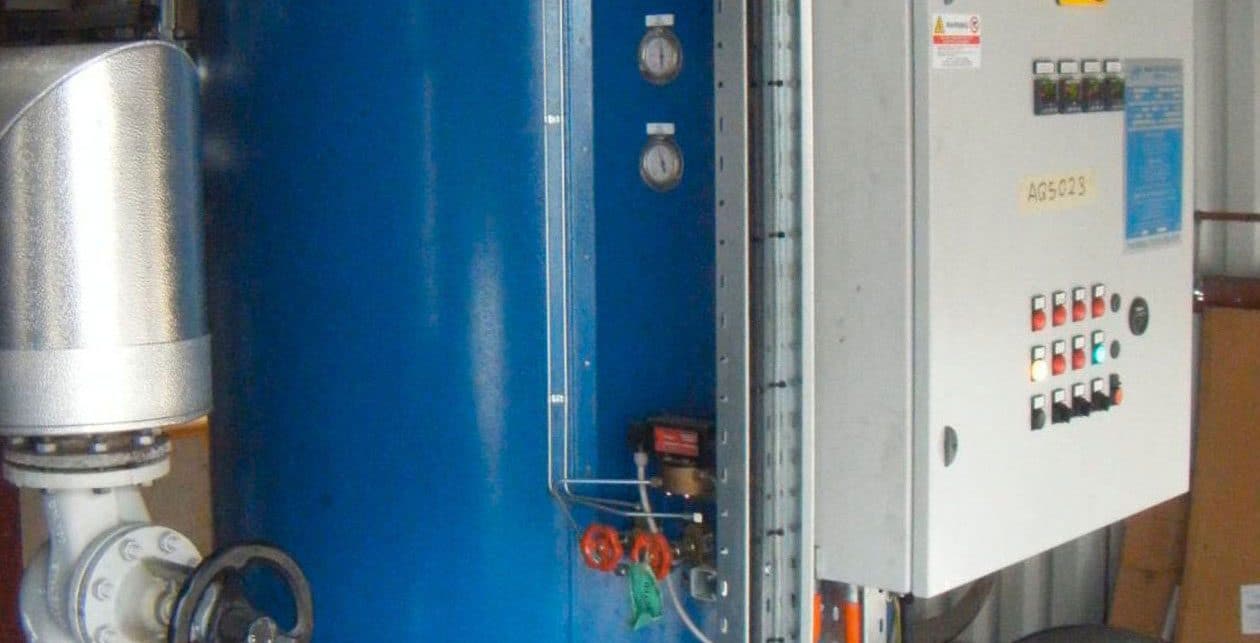

A fully automatic coil type, multi-pass thermal fluid heater complete with integrated burner, control system and safety devices, the TPC1000B provides optimal distribution of the heat, high fluid velocity in the exchange tubes and continuous flow monitoring to ensure long fluid life and the highest level of safety.

Customer Testimonials

— Loucas Antoniou, Engineering Manager at Bakkavor Meals London“The Thermal Oxidiser is the most efficient way of removing any smells and it’s also very straightforward to use. We have been a customer of Babcock Wanson for many years and have always enjoyed a good service.”

— Carbon Trust Annual Report 2009/10“A major carbon footprint reduction will be achieved when the scheme currently in progress to change the main boiler fuel from heating oil to gas is completed in summer 2010. This £900k project will reduce our carbon emissions via energy usage by around 15% by removing the need to use heavy fuel oil, as the new boiler plant will use natural gas as its main fuel source.”

— Webster & Horsfall“What we hadn’t expected initially though is the level of control the new system provides us with; it’s amazing. It alerts us to any potential issues, is easy to maintain (no annual statutory inspection is required) and is quick to respond. All that and it doesn’t take up much room.”

— Peter Connolly, Production Engineer at Vacu-Lug“The ESM 2000 installation, together with an ongoing programme of process plant lagging and steam trap maintenance, has enabled us to significantly reduce our gas usage and cushion the company against rising gas prices.”

— Dave Scrivens, Facilities Manager at Plastic Omnium“Babcock Wanson’s expertise and ability to provide a whole package made them the leading contender for this project. On further investigation, their proposal was also commercially viable, which sealed the deal.”

— Denis Kelly, Engineering & Construction Manager at Stolthaven Dagenham“The Thermal Fluid Heaters themselves were ideal for this project as they are based on mature technology and are well proven in the field. They are robust and also require very little maintenance.”

— Ian McQuarrie, Engineering Manager at Puredrive“During my three years here, the Steam Generators and Thermal Fluid Heaters have worked flawlessly. Babcock Wanson carries a good name in the business for both quality and equipment longevity. Their knowledge, company wide, is exceptional and the whole package from installation through to service is managed professionally.”

— Jason Hall, J&A Young Engineering Manager“We had estimated our steam requirements, but Babcock Wanson had the experience to understand that we had underestimated this. In fact, the erratic nature of the steam loads would have been impossible to meet under our existing spec. Babcock Wanson was able to identify this as well as provide a very energy efficient solution with a number of enhanced features”.

— Lee Bullen, Corrugated Services Manager at Board24“It’s running very well, both easy to use and efficient. The service from Babcock Wanson has also been very good.”

— Peter Shrimpton, Engineering Projects Manager at Bridgnorth Aluminium Ltd"We were unfamiliar with Babcock Wanson, but we’ve had no problems with it whatsoever; you simply switch it on and it works – simple as that! The service we have received from Babcock Wanson has also been great.”

You must be logged in to post a comment.