Showing all 6 results

Introduction

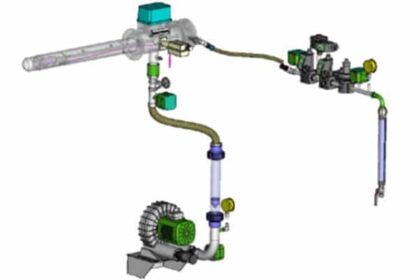

Babcock Wanson designs and manufactures industrial burners with high efficiency and environmental performance. This means that burners from Babcock Wanson provide the best available technology.

Unlike most industrial boiler manufacturers, at Babcock Wanson we also design and manufacture our own burners with outputs from 50 kW to 30 MW. This approach ensures our burners are perfectly matched to our complete boiler range and their specific combustion chambers for the highest operating efficiency. Customers also benefit from the peace of mind that comes from single source purchasing of both boiler and burner.

We have invested heavily in our burner ranges and worked with some of Europe’s leading technology partners. The result is improved energy efficiency through an increased modulation rate and a simultaneous reduction in emissions.

Babcock Wanson burners have been designed and rigorously tested for high performance when matched with one of our quality heating systems but can also be readily applied to other manufacturers’ equipment.

Find out about our combustion solutions by downloading the brochure.

Babcock Wanson burners are suitable for:

- New installations: Babcock Wanson guarantees the compatibility between our burner and fired equipment, thus ensuring the stated benefits, in terms of efficiency and emissions etc., are realised.

- Existing installations: The industrialist who modernizes his installation by the addition of a Babcock Wanson burner gives his existing equipment a new lease of life by improving efficiency and emissions performance.

What are Industrial Burners?

At its most simplistic, a burner is a mechanical device that mixes fuel and air together and, using an ignition device, provides a platform for combustion.

Over recent years great strides have been made in burner technology and their associated controls. These developments have resulted in high technology burners that provide the most accurate control of the fuel/air ratio throughout the burner firing range and extended turn down ratio with low levels of excess air and highest practicable operating efficiency.

Now, older process heating systems can often be given a new lease of life by replacing the burner with one of the latest models, not only extending the life of the system but also improving efficiency and turndown capability whilst reducing emissions.

Advantages of Industrial Burners

- Optimum design of burner for each boiler or heater

- No compromise when selecting the burner to suit the boiler

- Technical support with warranty extension up to 6 years

- CE marking covers the entire boiler / burner assembly

- Turndown ration 1:30 for special applications

- Excess air ˂15%

- Very low power solution: Thermoslow

- NOx as low as ˂60 mg/Nm³ for special applications

- Compliant with the most stringent international regulations

- Suitable for all liquid and gaseous fuels

- Dual fuel options available throughout the range

- From 50 kW to 22 MW output