e-Pack

Babcock-Wanson has over 50 years of experience in the design and manufacture of electric boilers. These boilers have been designed to meet the current challenges of energy optimisation and decarbonization of our industrial customers. Governments in each country are implementing very ambitious measures to achieve massive reduction in greenhouse gases.

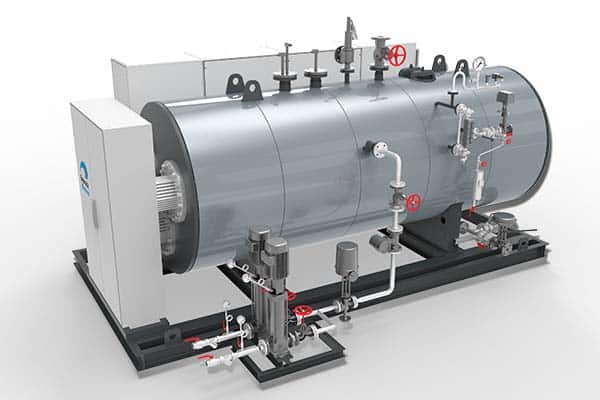

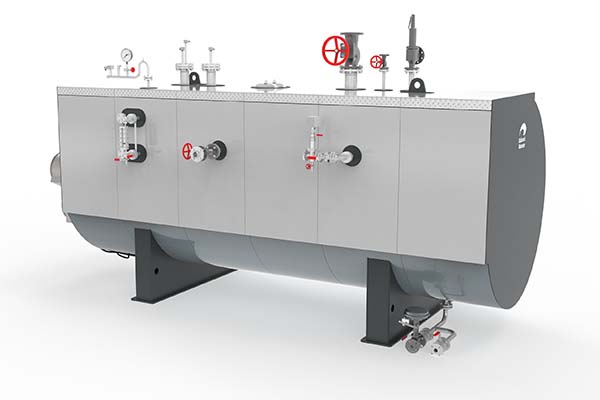

The e-Pack boiler has been developed by combining the best available technologies to achieve the highest level of efficiency, reliability and flexibility with zero emissions at the production site.

Environmentally friendly

The industrial electric boiler e-Pack boiler offers many environmental and operational benefits:

It does not consume any fossil fuel and therefore does not release any gaseous effluents into the atmosphere. From this pesrpective, the installation is very easy: There is no requirement for chimneys, fuel supply networks or storage tanks. In addition, no periodic monitoring of atmospheric emissions is required.

Efficiencies close to 100% can be achieved since all incoming electrical energy is converted into thermal energy (only minor heat losses through the surfaces are to be deducted).

Precise pressure control with multiple power stages allow the boiler to react quickly to load changes. This makes it possible to make quick starts to absorb available grid power when needed.

Robust construction for increased lifespan

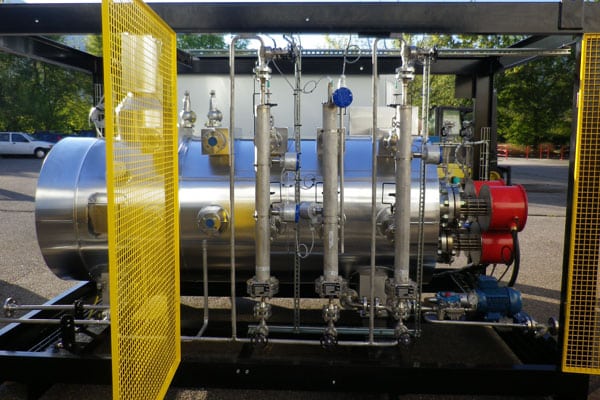

The e-Pack boilers consist of steel body with stainless steel immersion heaters, which offer numerous advantages in terms of performance, implementation and also for periodic maintenance operations. They are designed to allow both quick start-up and quick steam production, while protecting the immersion heaters from excessive stresses.

Economical Exploitation

The control and instrumentation allow exclusive Babcock Wanson operating modes that adapt to the constraints of all industrial processes. The boiler is equipped with the Navinergy monitoring interface, which enables both on-site and remote monitoring of operating parameters.

Easy installation and commissioning

The boiler is delivered ready to operate. All that is required is to connect it to the electricity, the feed water and the steam users. Commissioning is controlled and repeatable and avoids the difficulties that can make the commissioning of a fired boiler with burner more difficult from one site to another.

Why Choose the e-Pack Electric Boiler?

- Zero emission on site (CO2 – NOx – SOx)

- Efficiency close to 100%

- High turndown ratios

- Easy maintenance

- Robust construction for long life

- Connectivity with our system Navinergy

- Easy and flexible mode of operation

- High availability

- Easy to install

- Reduced operating costs

e-Pack Electric Boiler

| e-Pack | model | 300 | 600 | 900 | 1200 | 1500 | 1800 | 2250 | 3000 | 3600 | 4200 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Steam Output (1) | kg/h | 300 | 600 | 900 | 1200 | 1500 | 1800 | 2250 | 3000 | 3600 | 4200 |

| Power Output (1) | kW | 167 | 400 | 600 | 800 | 1000 | 1200 | 1500 | 2000 | 2400 | 2800 |

| Width A (2) | mm | 1400 | 1700 | 1700 | 1700 | 2000 | 2000 | 2000 | 2400 | 2700 | 2700 |

| Length B (2) | mm | 3700 | 4400 | 4400 | 4400 | 4500 | 4500 | 4500 | 5100 | 5100 | 4900 |

| Height C (2) | mm | 1800 | 2000 | 2000 | 2000 | 2300 | 2300 | 2300 | 2700 | 2700 | 3000 |

| Weight-fully flooded | kg | 2300 | 3800 | 3900 | 3900 | 5700 | 5700 | 5800 | 10000 | 10100 | 13500 |

(1) Power output at up to 8 barg based on feedwater at 95°C.

(2) Overall dimensions include immersion heater and boiler mountings.

Electric cabinet not included in the measurement

| e-Pack | model | 4800 | 5400 | 6000 | 6600 | 7200 | 7800 | 8400 | 9600 | 10800 | 12000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Steam Output (1) | kg/h | 4800 | 5400 | 6000 | 6600 | 7200 | 7800 | 8400 | 9600 | 10800 | 12000 |

| Power Output (1) | kW | 3200 | 3600 | 4000 | 4400 | 4800 | 5200 | 5600 | 6400 | 7200 | 8000 |

| Width A (2) | mm | 2700 | 2900 | 2900 | 2400 | 2400 | 2700 | 2700 | 2700 | 2900 | 2900 |

| Length B (2) | mm | 4900 | 5000 | 5000 | 7200 | 7200 | 7400 | 7400 | 7400 | 7500 | 7500 |

| Height C (2) | mm | 3000 | 3200 | 3200 | 2700 | 2700 | 3000 | 3000 | 3000 | 3200 | 3200 |

| Weight-fully flooded | kg | 13600 | 16000 | 16100 | 15600 | 15600 | 21500 | 21600 | 21700 | 25600 | 25800 |

(1) Power output at up to 8 barg based on feedwater at 95°C.

(2) Overall dimensions include immersion heater and boiler mountings.

Electric cabinet not included in the measurement