the Navinergy interface is a platform for monitoring the performance of your boiler room.

Smart and connected, the Navinergy interface is a platform for monitoring the performance of your boiler room. It is a powerful means to continuously optimise the energy and water efficiency of your installations.

Navinergy was developed by Babcock Wanson with the support of Energisme and its data management platform solution. Based on continuous remote monitoring, this unique and innovative system allows our customers to monitor their boiler room from any device. Whether on the boiler interface, from a computer on the other side of the world or from a smartphone, an operator can monitor the boiler room. With this system, Babcock Wanson is able to offer maintenance services with very high performance commitments.

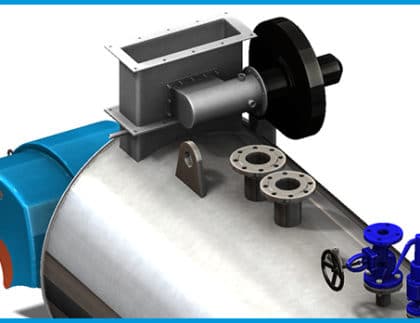

The Navinergy interface integrates all the components needed to supervise and operate the boiler room: control, regulation, recording, visualisation, communication. Its great modularity makes it a perfect tool for regulatory monitoring, maintenance and operation.

The Navinergy platform archives field data, formats it and allows you to access this data from any computer in the form of a graph or report, and to produce alerts to identify any deviations in the operation of your equipment. The graphs are highly customisable and allow you to dive into the operation of your boiler. Detailed reports can be generated at your convenience and are also sent periodically to our users. Finally, it is possible to subscribe to alerts in order to receive them directly by email according to customisable levels.

The eWater module is now an integral part of the Navinergy platform and monitors water quality to prevent boiler breakdowns. eWater enables operators to determine whether the water quality is in line with our specialists’ recommendations in order to ensure the life of your equipment. If not, corrective actions are proposed by the application. In case of major problems, a Babcock Wanson expert can also be notified to take proactive measures to solve the problem.

Technical characteristics of the Navinergy interface

- A touch screen user interface and a modern graphic design for the visualisation and archiving of all the events occurring on the boiler: drifts, alarms, tests and maintenance operations. It is possible to get a remote visualisation on computer, tablet or smartphone of the Navinergy interface.

- A controller for managing tests related to the operating mode, also acting as a communication router for remote control of equipment (drive, display, etc…).

- Permanent recording of the main operating parameters.

- A connectivity of the different equipment of the boiler and/or of the boiler room via a local Modbus TCP network.

- An autonomous on-board connection via a GSM modem, allowing remote access and assistance and enabling data transfer to the Navinergy platform.

Key features of the Navinergy platform

- Data archiving and traceability

- Interactive map to find all your equipment

- Summary pages with widgets of various types and shapes to visualise all field data

- Reports built on boiler data, exportable and sent periodically

- Alerts to identify equipment malfunctions

- Customisation of alert levels

- Customisation of monitoring criteria and parameters

- Water treatment monitoring with the e-Water module

- Module to list actions to be taken in the boiler room

You must be logged in to post a comment.