GOOD LOOP Concept – NOx Abatement

The GOOD LOOP Concept is an exclusive, innovative and environmentally friendly technology developed by babcock wanson

The Babcock Wanson Group is driven by the need to reduce the environmental impact of our industrial customers’ activities. The Burner Product Line team has been working for many years to reduce NOx emissions from our equipment and now offer this new concept:GOOD LOOP

In 2017 the “INTEGRAL” project was set up. Funded by ADEME as part of the Cortea call for projects (Agreement n°1781C0018 signed in 2017), the “INTEGRAL” project had the ambitious objective of finding a concept that would allow a 20 mg/Nm3 reduction in NOx on current gas equipment, while preserving the energy performance of the thermal equipment.

INTEGRAL’s innovative idea is to work on the boiler body with the aim to integrate a NOx reduction technique. Prior to 2017, the design of boiler bodies had never been done with the aim to reduce polluting emissions.

The efficiency and cost criteria were optimised, but the principle of involving the boiler in NOx reduction had never been studied. The Low NOx Boiler had yet to be invented.

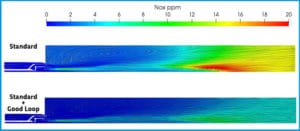

The burner team worked in two different ways. The first consisted of imagining different furnace shapes to increase internal recirculation. This approach was not conclusive, but it did allow us to optimise the firebox diameters of our boilers, resulting in a reduction of 10 mg/Nm3 of NOx.

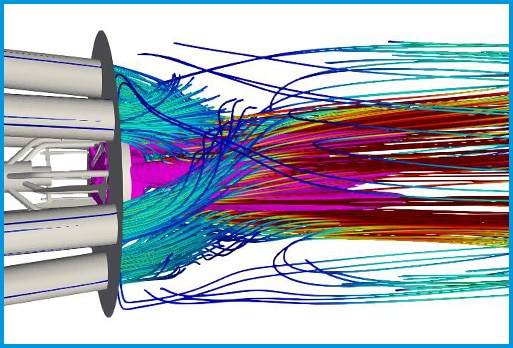

The second approach, based on a system of internal flue gas recirculation in the boiler, proved to be much more interesting. After a series of studies and modelling, the team will focus on this approach to develop the GOOD LOOP concept.

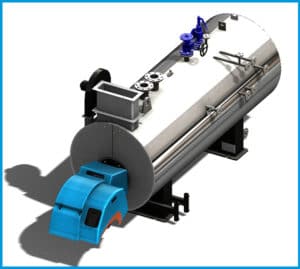

The GOOD LOOP concept uses EGR (Exhaust Gas Recirculation) as a NOx reduction technology.

The innovative character of the GOOD LOOP concept lies in the direct injection of recycled flue gases into the combustion chamber by an additional, dedicated fan.

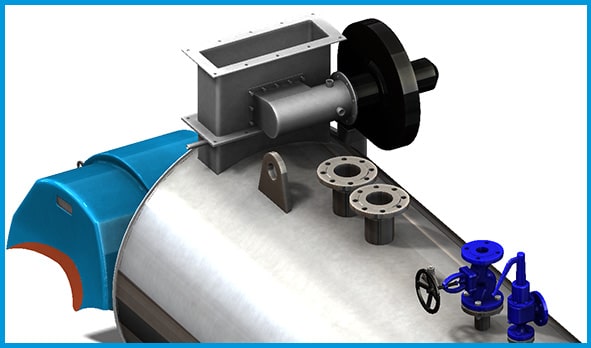

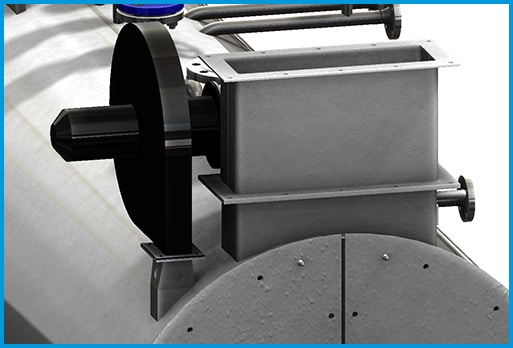

GOOD LOOP comes in the form of a compact kit, positioned upstream of the economiser, if applicable. It allows the extraction of flue gases at the boiler outlet. The boiler body is modified to allow the injection of flue gases into the furnace, upstream of the refractory blocks. The exhaust gas recirculation fan has its own variable speed drive and is controlled by an independent electrical panel.

Babcock Wanson is the only boiler manufacturer on the market that designs and builds its own burners. This unique expertise opens up opportunities for a low NOx boiler, with total control of the adaptation to the burner and its combustion, for a perfect boiler/burner synergy. The GOOD LOOP concept fully illustrates Babcock Wanson’s desire to offer its customers innovative and ever more environmentally friendly technologies.

You must be logged in to post a comment.