Plastic Omnium Installs Babcock Wanson Thermal Fluid Heaters At New Uk Site in Birmingham

Low NOx emission heaters in the production of parts for the new Range Rover

Plastic Omnium, a manufacturer of plastic parts for the automotive industry, has installed two Babcock Wanson Thermal Fluid Heaters in its new factory in Birmingham.

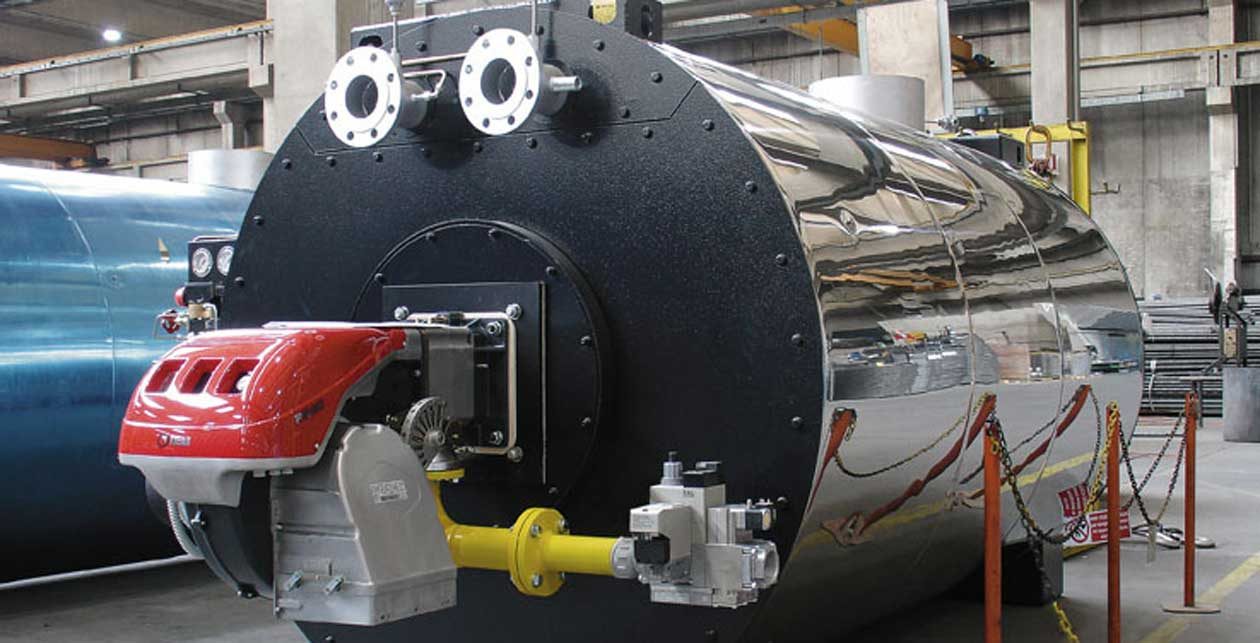

The Babcock Wanson TPC600LN Low NOx emission heaters are being used by Plastic Omnium in the production of parts for the new Range Rover Evoque. The thermal fluid heaters heat the compression moulding press tools to 220°C, enabling the Special Compound to be moulded to the correct shape.

The TPC Series are fully automatic coil type, multi-pass thermal fluid heaters complete with integrated burner, control system and safety devices. They provide optimal distribution of the heat exchange, high fluid velocity and specialist flow control for long fluid life and the highest safety; all this coupled to very low emissions and low running costs.

The Solution and Client Reaction

The TPC600LN used at Plastic Omnium are fired on natural gas and have been supplied by Babcock Wanson with a special process fluid mixing vessel to ensure a common flow temperature to the production machines, irrespective of the number of machines or heaters on-line at any one time. They were specified by Plastic Omnium for the new UK site based on Babcock Wanson’s reputation for quality product and a professional service.

Dave Scrivens, Facilities Manager at Plastic Omnium, comments: “Babcock Wanson’s expertise and ability to provide a whole package made them the leading contender for this project. On further investigation, their proposal was also commercially viable, which sealed the deal.”

Babcock Wanson offers a complete range of products and services for boiler houses and other process heating needs, from steam boilers, thermal fluid heaters, rapid steam generators and hot water boilers to VOC and odour treatment by thermal oxidation, water treatment or process air heating solutions. The company aims to help optimise customer’s energy production with high quality products and efficient service.

Customer Testimonials

— Loucas Antoniou, Engineering Manager at Bakkavor Meals London“The Thermal Oxidiser is the most efficient way of removing any smells and it’s also very straightforward to use. We have been a customer of Babcock Wanson for many years and have always enjoyed a good service.”

— Carbon Trust Annual Report 2009/10“A major carbon footprint reduction will be achieved when the scheme currently in progress to change the main boiler fuel from heating oil to gas is completed in summer 2010. This £900k project will reduce our carbon emissions via energy usage by around 15% by removing the need to use heavy fuel oil, as the new boiler plant will use natural gas as its main fuel source.”

— Webster & Horsfall“What we hadn’t expected initially though is the level of control the new system provides us with; it’s amazing. It alerts us to any potential issues, is easy to maintain (no annual statutory inspection is required) and is quick to respond. All that and it doesn’t take up much room.”

— Peter Connolly, Production Engineer at Vacu-Lug“The ESM 2000 installation, together with an ongoing programme of process plant lagging and steam trap maintenance, has enabled us to significantly reduce our gas usage and cushion the company against rising gas prices.”

— Dave Scrivens, Facilities Manager at Plastic Omnium“Babcock Wanson’s expertise and ability to provide a whole package made them the leading contender for this project. On further investigation, their proposal was also commercially viable, which sealed the deal.”

— Denis Kelly, Engineering & Construction Manager at Stolthaven Dagenham“The Thermal Fluid Heaters themselves were ideal for this project as they are based on mature technology and are well proven in the field. They are robust and also require very little maintenance.”

— Ian McQuarrie, Engineering Manager at Puredrive“During my three years here, the Steam Generators and Thermal Fluid Heaters have worked flawlessly. Babcock Wanson carries a good name in the business for both quality and equipment longevity. Their knowledge, company wide, is exceptional and the whole package from installation through to service is managed professionally.”

— Jason Hall, J&A Young Engineering Manager“We had estimated our steam requirements, but Babcock Wanson had the experience to understand that we had underestimated this. In fact, the erratic nature of the steam loads would have been impossible to meet under our existing spec. Babcock Wanson was able to identify this as well as provide a very energy efficient solution with a number of enhanced features”.

— Lee Bullen, Corrugated Services Manager at Board24“It’s running very well, both easy to use and efficient. The service from Babcock Wanson has also been very good.”

— Peter Shrimpton, Engineering Projects Manager at Bridgnorth Aluminium Ltd"We were unfamiliar with Babcock Wanson, but we’ve had no problems with it whatsoever; you simply switch it on and it works – simple as that! The service we have received from Babcock Wanson has also been great.”

You must be logged in to post a comment.