Industrial Water Softening

Water flow from 0,125 to 20 m3/h

Resin capacity from 25 to 550 litres

With over 60 years of experience in water treatment, Babcock Wanson offers a wide range of water softening equipment for industrial use. Over a thousand softeners have been installed at sites of various sizes, with a particular focus on water for steam boilers.

Softening is a method for eliminating calcium and magnesium dissolved in water. These elements must be removed before use in boilers because they tend to precipitate when heated, forming deposits within the equipment. These deposits reduce heating efficiency and can cause internal circuits to overheat, potentially leading to failure.

Industrial Water Softening Equipment

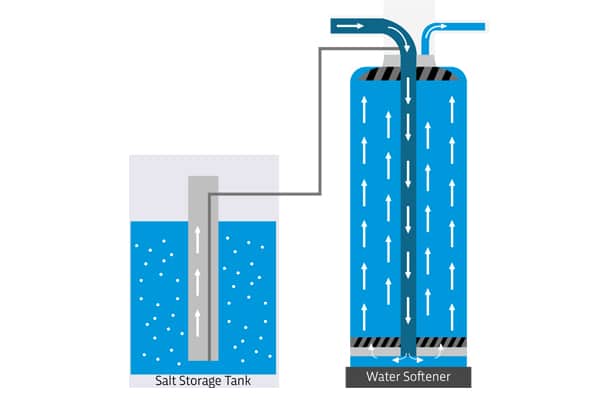

Water softeners operate on the principle of ion exchange. Undesirable calcium (Ca2+) and magnesium (Mg2+) ions are exchanged for an equivalent amount of sodium (Na+) ions. The exchange takes place in a pressurised tank filled with resin. As this exchange is not perpetual, once the sodium charges are exhausted, the resin must be regenerated using brine (NaCl) before a new production cycle can begin.

Babcock Wanson offers a wide range of softeners to suit all types of boilers and processes. For industries requiring specific approvals (ACS, etc.), suitable equipment and resins can be provided.

Reduced Operational Costs

With a commitment to reducing operating costs and conserving water, we also offer backwash regeneration softeners. Although they require a slightly more sophisticated installation, and are therefore more expensive to purchase, this process reduces salt consumption by 30 to 40% and also reduces service water consumption by nearly 40%.

High Efficiency

Experience with the specific requirements of boiler house water treatment means that Babcock Wanson understands the requirement for softening equipment quality, robustness and reliability. The PLC and Operator HMI screen provided with the largest capacity softeners ensures high flexibility, minimal maintenance and straightforward monitoring.

Ease of Operation

For large installations, when it becomes too difficult to load a salt tank manually, Babcock Wanson supplies its water softeners with a brine preparation silo. Fine salt is stored in bulk in a storage silo, which is then responsible for preparing the brine and distributing it to one or more water softeners. Regeneration can be triggered by the volume of water produced or by a timer. After-sales service for the equipment is provided by the Babcock Wanson Group’s international network and its local service technicians.

Full Range of Equipment

- Water flow rate from 1 to 20 m3/h

- Simplex, duplex or multiplex configurations

- Bronze or Noryl central valves

- On-board or remote control timer depending on the application

- Supplied with salt tank and accessories

For all non-standard applications or higher flow rates, Babcock Wanson offers customised installations tailored to the customer’s required flow rate.