Demineralisation by Resin Exchange

Custom-built equipment

Demineralisation by resin exchange is a water purification technology which removes dissolved ions from water and replaces them with other ions of the same or similar electrical charge (hydrogen H+ or hydroxide OH-) to produce pure water. Typical cations targeted for removal are calcium (Ca++), Magnesium (Mg++), Sodium (Na+), Potassium (K+) and Iron (Fe++). Typical anions targeted for removal are Bicarbonate (HCO3-) Chloride (Cl-), Sulphate (SO4–), Nitrate (NO3-) and Silica SiO2). The performance of a demineralisation process depends on the incoming water condition, system design (co-flow or counter-flow), type of resin used and regenerant type and concentration. In industrial processes, the demineralisation method is usually applied when very low dissolved salt content is required in the process water or in boiler feed water.

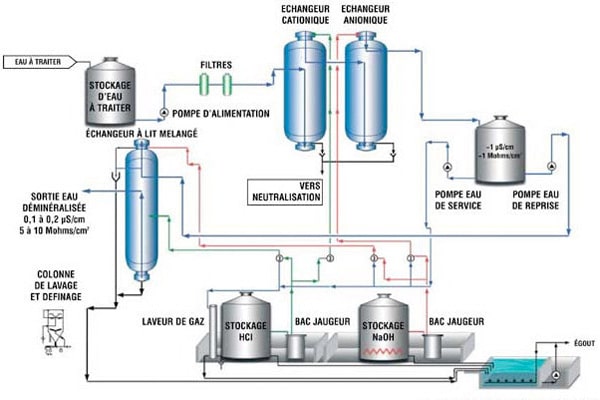

Babcock Wanson has developed the HRW© process which is based on a counter-current regeneration process. The process, depending on downstream requirements, removes salts (and silica) by using cationic and anionic resin bed exchangers as a primary treatment and a mixed bed as a finishing treatment. It produces high quality water with very low mineral content and low conductivity.

HRW© Demineralisation by Resin Exchange application

- Boiler feed – As water is evaporated within a steam boiler, dissolved minerals can precipitate and deposit on the heating surfaces. These salts can have corrosive properties and scale on heat exchange surfaces decreases the effectiveness of heat transfer, resulting in at the very least reduced efficiency and often leads to equipment damage and ultimately failure. The HRW© process produces pure boiler feed water, which removes the risk of energy wastage, reduces downstream chemical treatment costs and assures the availability and safe operation of the boiler.

- Industrial process water – Demineralisation of water is often the preferred process for producing process water for the food and beverage industry, steel mills, etc.

- Technical waters – Technical water produced by demineralisation is essential for use as turbine wash, cooling water for engines and injection water for mixing with fuel to reduce emissions of NOx and CO2 in Marine and Offshore processes and in Cogeneration, etc.

Advantages of HRW© Demineralisation by Resin Exchange

The suspended and counter-current regeneration associated process has many advantages in terms of regenerating reagents consumption and water quality produced:

- Obtaining low conductivity and consistent water quality over the cycle duration.

- Fully automated equipment and configurable PLC (Programmable Logic Controller) for safety and alarm management.

- No backwash phases.

- The volume of service water and discharged effluent is significantly reduced.

- Reduction of the regeneration time.

- Reduced reagent consumption (from 30% to 40%).

- Reduced installation size.